Clothing labels have the functions of beautifying the appearance and improving the quality of clothes. They are an indispensable part of clothing and have their own characteristics and existence. So, how much do you know about woven labels and printed labels? The following will introduce to you the differences between woven labels and printed labels.

Print labels?

Printed labels are more popular nowadays. They are a kind of identification material that directly prints text, pattern or trademark on the label through printing process. Patterns and information are printed on labels through heat transfer or screen printing technology. Printed labels can achieve more colors and complex design effects, and some special processing can also be added to the labels, such as punching, anti-counterfeiting, etc.

Advantages of printed labels:

Rich and diverse colors: Because it uses printing, the colors are rich, full, gorgeous, high-definition, and the product is more fashionable.

High production efficiency: Printed labels have a fast turnaround and can be produced and delivered quickly.

Disadvantages of printed labels:

Poor durability: some printing processes are not good and they fade easily.

Lower overall quality: Printed labels don’t look or feel as high quality as other types of labels, and they are usually thinner.

Woven labels?

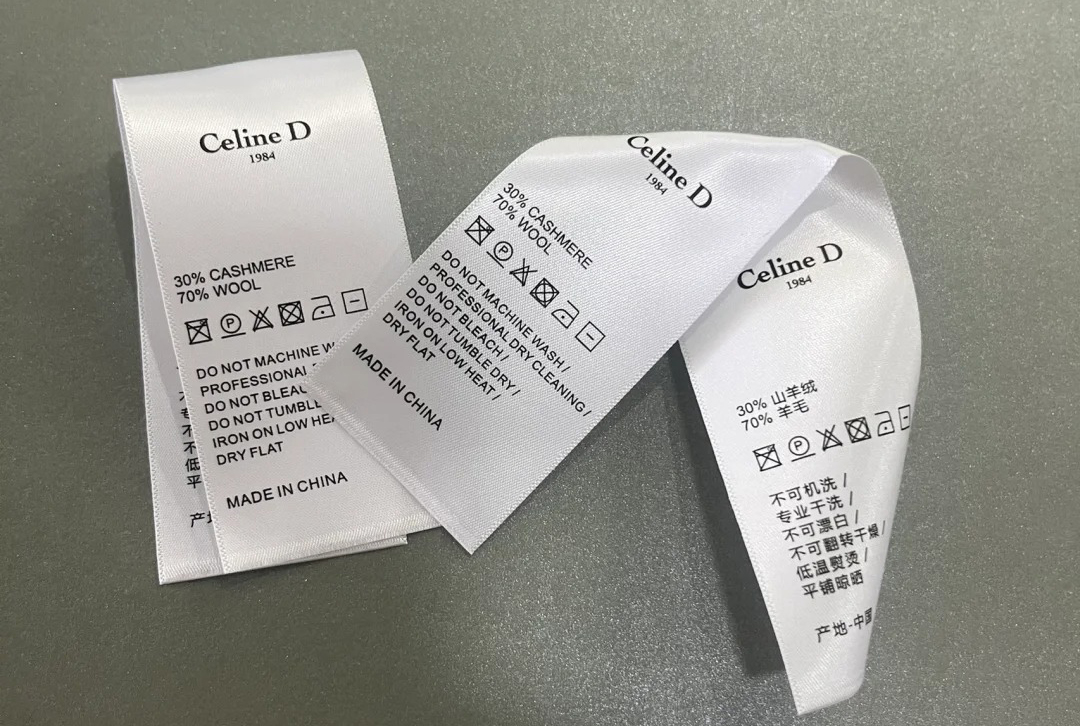

Woven labels are woven on a loom by fixing warp yarns and using weft yarns to express text, graphics, letters, numbers, three-dimensional logos, color combinations, etc. Woven labels are usually made of fiber materials such as polyester, cotton or nylon, which have better durability and texture. Woven labels are mainly used to display information such as brand logos, sizes, washing instructions, etc., and can be sewn or affixed to products.

Advantages of woven labels:

High Quality: Many high-end fashion brands tend to use woven labels.

Better durability: They are durable and will not wear out or fade after years of wear.

Soft touch: Labels are generally made of polyester thread or cotton thread interwoven, so the surface is soft and shiny.

Disadvantages of woven labels:

Costly: Woven labels take more time to produce and cost more to set up.

Low output: Due to the complexity of the entire production process, the output is lower than printed labels.

The cut edge is hard and can cause irritation: if the burnt edge woven label is not cut properly, it will be uneven, which will make the neck of the person wearing the clothes very uncomfortable.

Which is better,woven labels or printed labels?

Compared with the two, woven labels and printed labels have their own advantages and disadvantages. When choosing, you need to consider your usage scenarios and needs. Printing labels is faster, more suitable for mass production, and usually cheaper. However, it is more suitable to choose soft and printed label materials for close-fitting underwear, underwear and other skin-friendly items. So the one that is suitable is the best, not necessarily the one that is more expensive.