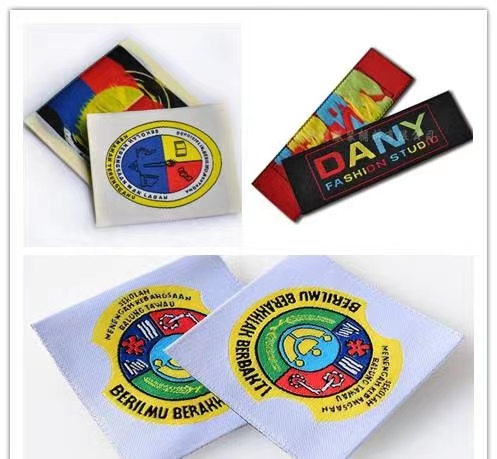

The trademarks that are often used on clothing mainly include woven labels, printed labels, and silk-screened trademarks. The clothing trademarks that are often seen when buying clothes are mostly made of two kinds of materials: woven labels and printed labels. Woven labels and printed labels are different. They have different characteristics. Let’s learn how to distinguish between woven label trademarks and silk screen trademarks?

1.woven label trademark

Woven labels are cloth labels that are placed on clothes and pants and contain text, fonts, and LOGO patterns.

Woven label trademarks are woven on a woven label machine by fixing the warp yarns and using the weft yarns to express text, graphics, letters, numbers, measurements, color combinations, etc. They are high-end, strong, clear lines, and soft to the touch. Woven labels are all made of yarn to express patterns. The woven labels are different from the original graphic design, so it is impossible to make large quantities without making a sample for confirmation.

2.According to the craftsmanship, woven labels are mainly divided into two types: woven edge trademarks and trimmed edge trademarks.

Selvedge trademark

When the required trademark is woven according to the required width at one time, it is called a selvedge trademark.

Disadvantages: Textile edge labels are generally made of satin labels, which have low output. Since the satin background color is difficult to express, hot stamping/dying and other processes are required to solve this problem.

Advantages: This process avoids many shortcomings of trimming. It is divided into flat/satin surfaces. It feels soft and stiff. It is suitable for use in high-end clothing products; such as fashion, suits, etc.

Selvage machines: wooden shuttle machines and crochet machines.

Trim label

On a special high-speed machine, a whole piece is woven like woven cloth, and then cut into strips according to the specified width.

Advantages: Due to the thermal melting properties of polyester, the yarns will stick to each other when cut, without falling apart, and the output is high.

Disadvantages: There is no selvedge effect. Ultrasonic cutting is better than ordinary electric heating knife.

Note: The setting of a machine to produce flat or satin surfaces is generally relatively fixed. The trimmed satin edge cannot exceed 10.8CM, and the selvage edge generally cannot exceed 5.0CM. In addition to the width, total length of each color, and craftsmanship, the cost component of a cloth label also includes the type of yarn used. JB series yarns are commonly used internationally.

Plane mark

Cloth labels have a cloth structure, with one warp and one weft intertwined up and down, which is called a simple plane label. Generally speaking, the warp yarns are fixed, either black or white, so they are divided into black flat and white flat. Light-colored background colors generally use white flat, and dark colors generally use black flat.

The pattern and color of the cloth label are mainly expressed by the weft yarn, and the color expressed will be different due to the different effects of crossing with the warp yarn.

Satin label

Satin cloth labels are all interwoven with warp and weft. In addition to improving the quality by doubling the weft, there is also the possibility of doubling the warp. This process is a satin structure.

By doubling the warp, the texture of the fabric label becomes softer and smoother. Because after the warp is doubled, the density is too high, the weft cannot express the pattern well, and the color of the bottom cannot be made very flexible. Certain color requirements can only be realized through post-processing.

3.Silk screen trademark

Silk screen printing is suitable for any media printing: paper, plastic, PVC materials, cloth, glass, etc.

Silk screen printing is more suitable for high-quality and large-volume paper printing. It is a very flexible processing technology.

Principle: Basically like wax paper mimeograph, but the version is different. There is a special screen printing version. It is direct printing and the ink is thick.

Features: The plate making cost is low, and it can basically be applied to any media printing, including paper, plastic, PVC materials, cloth, glass, etc.

For example, simple cloth trademark processing in small batches has obvious shortcomings. It cannot be very accurate and cannot perform four-color overprinting. Even if it can, the dots are relatively rough. Of course, machine printing will be better than manual printing. Commonly used auxiliary materials for screen printing processing include: plastic hang tags, various leather tags, various PVC labels, ribbons, special printing labels, etc. The combination of silk screen printing and offset printing can also create special effects on clothing tags.

The application of silk screen printing is more flexible than the application of woven labels, and can be used for paper tags, fabric trademarks, ribbon printed labels, PVC materials, glass, etc. The production principle of woven labels is the same as that of woven cloth, while silk screen labels are printed on cloth based on the printing principle. Silk screen labels look more beautiful than woven labels, with a smoother surface and are generally used for high-end clothing labels.