I believe many people will have such an experience. Wearing a comfortable piece of clothing can cause skin itching due to the presence of the back collar label, leading to a decrease in the wearing experience. So why do businesses design neckline labels with extremely poor wearing experience at the back of the collar? This is naturally due to the merchant’s thoughts on brand promotion.

Let’s imagine that if the logo is placed under the clothing, there will be very few people who can see the name of the clothing. Merchants naturally do not want to waste this opportunity for secondary promotion and promotion.

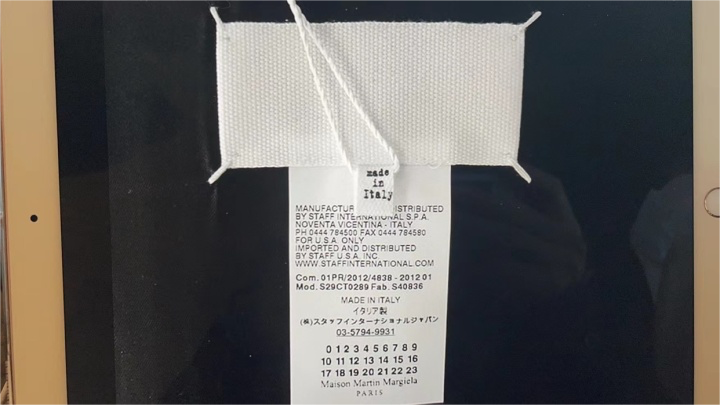

Therefore, it is not difficult to see many clothing logos appearing on various obvious parts of the clothing in daily life. For example, some clothing may not be suitable for trademark exposure, and merchants may choose to directly sew a woven ribbon logo on the inner lining. If some clothing is also not suitable for inner lining, then merchants will naturally choose the simple and rough method of labeling the back neckline. Compared to custom woven lining, custom woven trademark is definitely more cost-effective.

In fact, in order to avoid discomfort when wearing, merchants have come up with solutions. One is to start with the processed material, and the other is to design the fixed collar logo to be detachable, but we have not found any. If observed carefully, it is not difficult to find that the fixed threads of the collar are all large stitches that are easy to remove.

Simply put, if there were no uncomfortable issues on a piece of clothing, everyone’s attention would not mind its existence. So why does this neckband make people feel uncomfortable? It’s actually related to the manufacturing process of the neckband.

There are two main types of production processes for labels, one is called woven labels, and the other is called printed labels. The difference between the two is that printed labels are trademarks printed with ink, including washing labels, size labels, hang tags, and certificates of conformity.

Nowadays, many clothing factories use marking as a printing method mainly because printing marks is more efficient and cost-effective compared to weaving marks.

And woven labels are woven by machines with high precision, resulting in more delicate and clear content. Even small fonts can be woven very clearly. And it can be woven in multiple colors, but the disadvantage is that using hot cutting technology will result in obvious cuts at the edges, and the slightly hard cut edges will have a certain prickly feeling.

However, with the improvement of modern technology, there is another cutting method that uses ultrasonic cutting. Although there are obvious cutting edges, the feel of the edges is much smoother and won’t prick the skin. However, the price will naturally be higher than hot cutting.

Of course, there is also a wooden shuttle machine satin weaving mark, which is a type of woven edge fabric mark that can be woven in one go according to the width requirements. This process avoids many drawbacks of edge cutting, but the yield is relatively low.

The characteristic is that after weaving the trademark from the machine, it becomes a complete piece, with a soft touch, very soft edges, and a glossy surface. But its disadvantages are also very prominent, such as low production efficiency and long production time, inability to make colored backgrounds, large needle holes in woven fonts, and inability to weave too complex shapes and text effects.

The only available colors are white, beige, black and other base colors, which are more suitable for high-end clothing items such as fashion and suits.

In addition, there is also a hook edge machine advanced weaving label, which has a thick and textured finished product effect. It has a locking edge process (that is, the edge is no longer a separately processed collar, but is woven as a whole, just like the edge of a sweater), which can maintain the collar label permanently without deformation. It is a commonly used processing technology for many top tier brands.

In the production of collar labels, due to differences in processing costs, material usage, and machines, the wearing experience may also vary. However, each process cannot be replaced, each with its own characteristics. If you really feel uncomfortable, it is best to dispose of it directly and effectively.