Woven labels are not only a product identification, but also a display of brand image, so their production technology and quality requirements are very high. How are woven labels made? The following introduces a common woven label production process:

Design artwork

According to the LOGO or brand image provided by the customer, we design the structure, color, font and other elements of the mark, and produce a mark design drawing. The design drawing will contain elements such as text, graphics and logos.

plate making

According to the mark drawing, the plate making of the woven mark is carried out. There are two types of plate making: relief printing and flat printing. Letterpress printing is generally used. The accuracy and quality of plate making directly affect the quality of woven labels.

Material selection and color fixing

According to the marking artwork and customer requirements, select the appropriate yarn and material for woven label production, such as polyester fiber, nylon, cotton, etc. Color is an important factor, choose the appropriate color according to the design drawing. Typically colored dye or pigment inks are used. The choice of color depends on the material and design drawing requirements.

Weaving

High-speed looms are used for weaving, and the accuracy of yarn tension, density and color must be ensured during weaving.

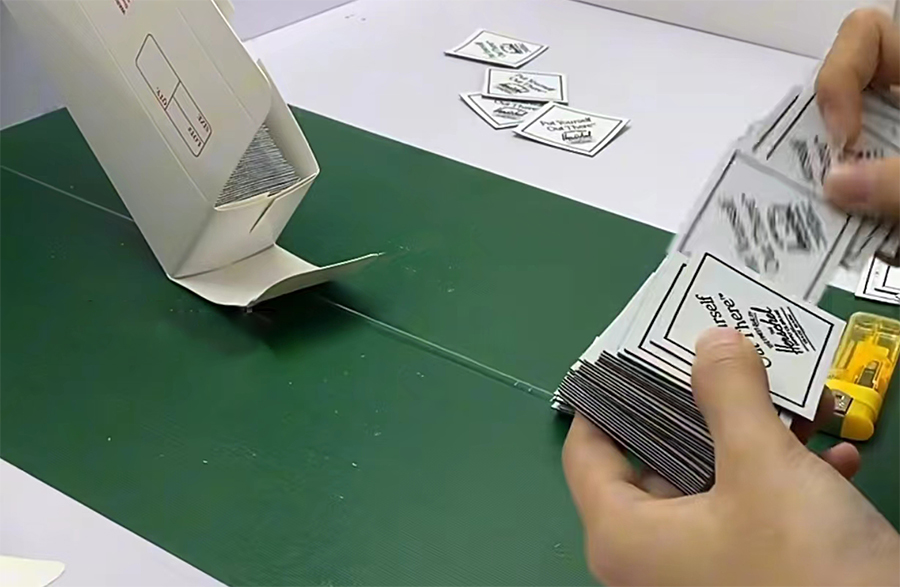

Cut and sew

After weaving is completed, post-finishing is required, including heat setting, cutting, folding, hemming and other treatments. Heat setting is to treat the woven mark at high temperature to maintain its shape. Cutting is to cut the mark into corresponding sizes according to the size requirements. Folding and hemming are to facilitate the sewing and use of the mark.

Inspection and packaging

After the woven label production is completed, quality inspection must be carried out. This includes checking the accuracy of the pattern, the vividness of the colors, the firmness of the threads, etc. After passing the inspection, they will be marked and classified according to customer requirements, and the woven labels will be packaged to ensure that they are not damaged during transportation and storage.