Woven labels are widely used. They are affixed to clothing, shoes, and bags. These are the logos of clothing brands and play a key role in the clothing market: information description, brand identification, and brand image enhancement.

However, there are many steps in making custom woven labels. In order to ensure high-quality production, every link is crucial. Next, the production process is explained in detail in this article:

How to make woven labels? -6 steps

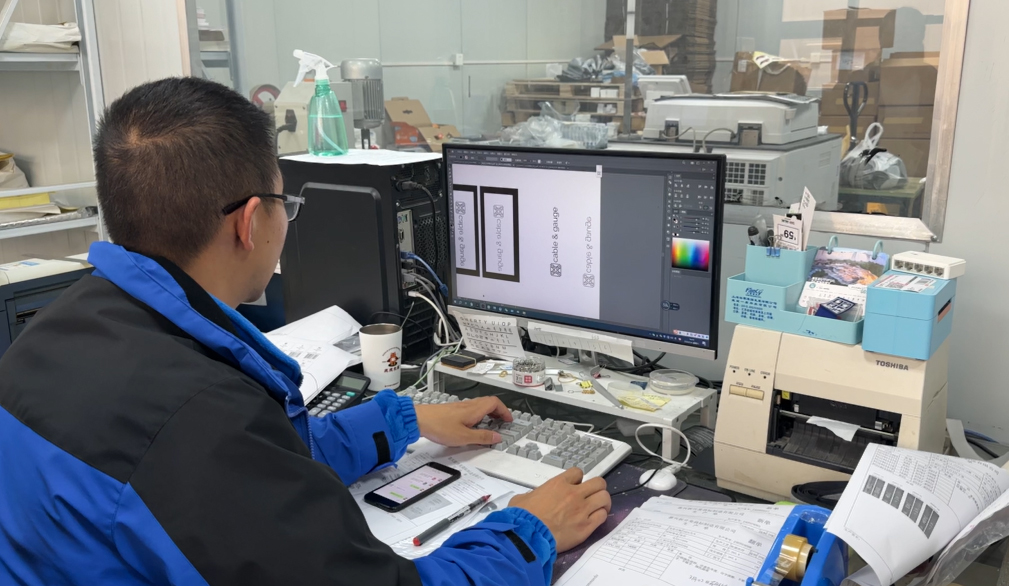

1、Determine the design draft

According to the customer’s needs, determine the required size, pattern, text, etc., and use design software (such as CDR or AIr) to design the first draft of the woven label.

2、Yarn matching and yarn selection

Choose the appropriate yarn material according to the customer’s needs or design draft. Commonly used are polyester, nylon, cotton, etc., and sustainable materials choose organic cotton and recycled polyester.

3、Make a sample

Enter the design draft into the computer program of the loom. Before large-scale production, make a sample first. You can make final adjustments based on the sample.

4、Weaving

After the sample is confirmed to be fine, large-scale weaving is carried out, the parameters of the weaving machine are set, the yarn is assembled to the loom to start weaving, and the weaving process is monitored to ensure the quality of each label is consistent.

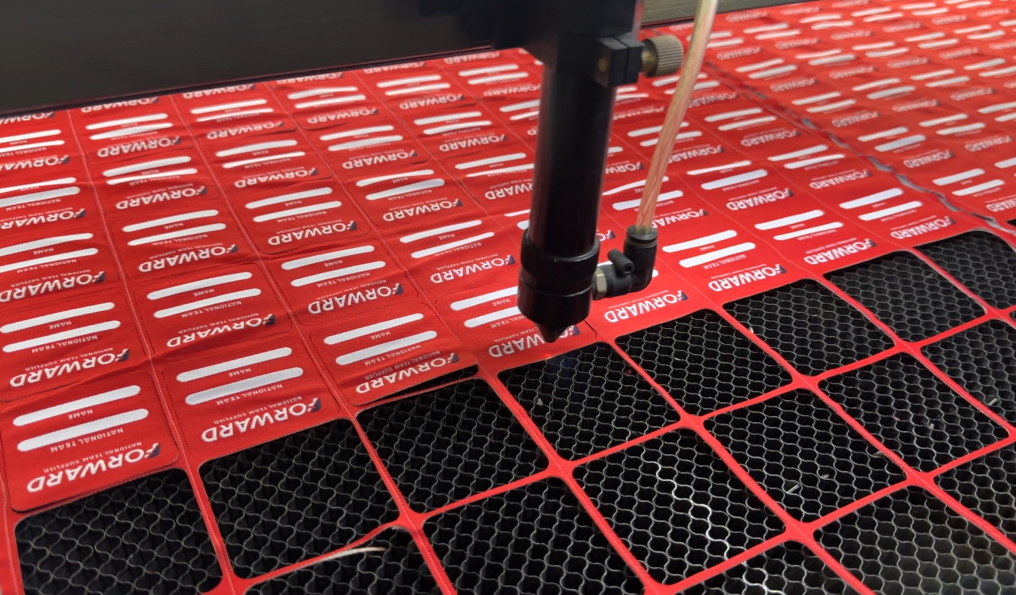

5、Cutting woven labels

Use a cutting machine to cut the woven labels according to the size required by the customer.

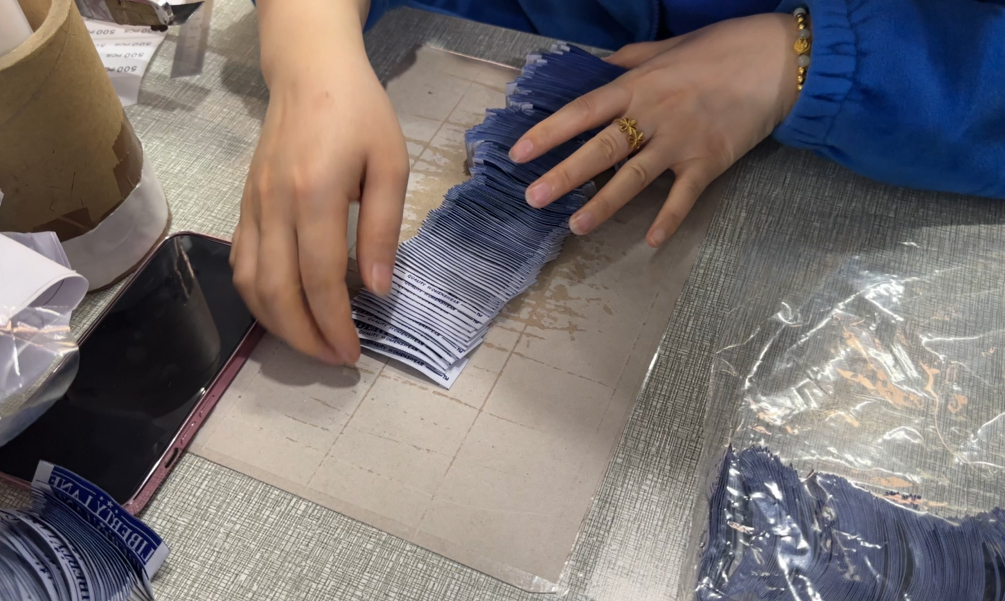

6、Quality inspection and packaging

Strict quality inspection is carried out on each batch of woven labels to ensure that there are no problems. The inspected woven labels are packaged with appropriate packaging materials.

Things to note when making woven labels:

Two details to pay attention to in the production process of woven labels:

1、Color matching problem: pay attention to the quality of the yarn to avoid fading and uneven dyeing.

2、Post-process cutting: ensure that the cutting edges are neat and free of burrs.

Generally speaking, as long as the color and post-process are done well, there will be no mistakes in the woven labels.