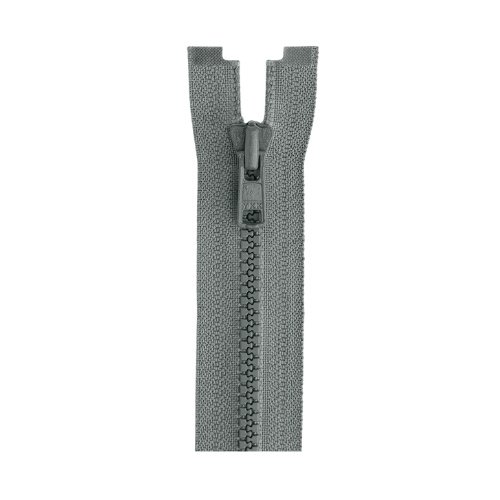

Plastic Zipper Manufacturer in China

Wirwear manufactures custom plastic zippers with multiple advantages, including the following:

- Rustproof

- Come in bright colors

- Waterproof

Wirwear Custom Plastic Zipper

Plastic zippers are kind of chains, having molded plastic teeth. These molded plastics typically consist of acetal resins. Besides, some polyethylenes are present in its structures. Plastic zippers have multiple components, including top and bottom stops, teeth, polyester tapes, and sliders. They also have bound opening edges with various textile and fabric materials.

Wirwear is a professional plastic zipper manufacturer based in China. We are committed to providing top-quality zippers at reasonable wholesale prices. Moreover, we offer various artistic and long-lasting plastic zippers that suit different applications. Wirwear utilizes the latest production technology and extensive expertise in manufacturing. We also provide satisfying services from design and production to delivery.

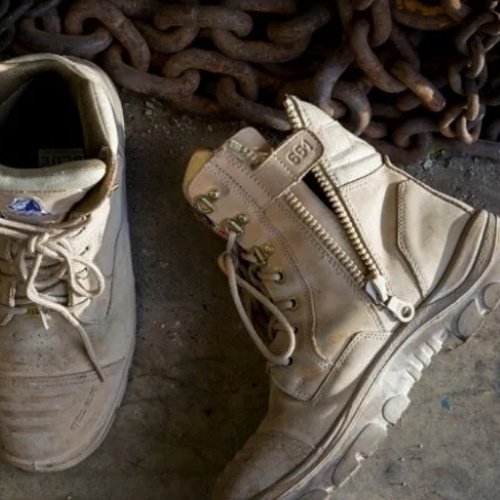

Open-end plastic zippers have a customizable length, perfect for bags, shoes, and garments. Different colors, like Pantone and CCC, are available.

The plastic close-end zippers are OEKO-TEX100 ISO9002 certified and approved. They are available with customizable logos, colors, teeth designs, and lengths.

Two-way plastic zippers are suitable for home textiles, garments, and shoes. They come with an auto-lock slider yet are customizable with regular teeth.

Plastic zippers with tailored sliders are typically designed with open-end and fashionable sliders. They are waterproof and ideal for bag and shoe applications.

Plastic zippers with regular sliders come in different sizes, including #3, #5, etc. These zippers are available with single or double sliders.

Plastic top and bottom-end zippers have sustainable features with customizable sliders. Custom tape colors are available. These zippers have wide usage.

Plastic Zipper By Zipper Sizes

Plastic Resin Zipper By Application

Plastic Zipper Wholesale Benefits

You can get custom plastic zipper products at affordable costs. That assures excellent business profit.

Customers can purchase low minimum orders of plastic-made zippers according to their budget or market needs.

Wirwear uses a streamlined manufacturing technique, ensuring complete orders. From concept to extensive production.

Custom plastic zippers are developed by experienced designers who assist customers through the entire production process.

Wirwear has professional quality control auditors who assess and check every zipper part to ensure the quality and functions.

We operate with outstanding worldwide logistics companies that guarantee quick and safe deliveries within 5-7 days.

Why Choose Wirwear Plastic Zipper

Wirwear does plastic zipper dyeing procedures, guaranteeing that every zipper comes with bright colors. We make sure their hues will last a long time without chipping.

We provide exceptional cloth tapes that ensure zipper teeth. Customers can also guarantee cloth tapes that withstand tearing and wearing due to washing and sewing.

As one of the leading manufacturers of plastic zippers, Wirwear has comprehensive slider options. You can select the most suitable ones for specific applications.

All samples and finished plastic zippers go through a variety of quality testing. That ensures customers achieve increased durability of products and function maintenance.

The first thing to consider is the plastic zipper’s durability offered by trusted manufacturers, like Wirwear. It is also essential to know the suitable color brightness and smoothness of their sliding actions.

Moreover, the correct alignment of teeth is also vital when zippers are opened and closed multiple times. Also, ensuring that the zipper tab is not breakable for smooth gripping is an important factor.

The resin zippers are more convenient to use and flexible for various applications than nylon zippers.

Resin ones feature wear and heat resistance and are waterproof compared to nylon-made zippers. They are stiffer than nylon ones. And importantly, resin zippers have adaptable quality for customization. They work well with vivid colors and gem inlays.

Yes, plastic zippers are highly regarded for their extreme temperature resistance. And in the dyeing process, the color retains longer.

And they are ideal for outdoor products. Resin zippers have robust large teeth, are more flexible, and adequate for lavish customization. Additionally, these plastic zippers don’t corrode, unlike metal zippers.

To differentiate both #3 and #5 zippers’ features: the wideness and qualities should take into account.

For example, the #3 multipurpose zipper has 1mm tape and 3mm wide teeth. It’s given that #3 is more flexible. However, #5 is the typical zipper for medium size products. The #5 with 1.25mm wide tape and 5mm wide teeth are convenient for upholstery and tote bags. So, technically #5 is much more stable.

Plastic zippers can be made from several different types of materials. And we may already be familiar with the most common types.

Coated PVC Zipper. They have good water resistance long-chains. Handy for tents, bags, clothing, and household textiles.

PP Zipper. It has high rigidity and a special sealing layer.

EVA Zipper. This zipper type consists of resins and compounds.

EVA Zipper with Superior Use. There are more to conclude, but these are the common types that meet the needs.